Business excellence

20 years of technology precipitation and professional coaching team to help companies achieve business excellenceERP system scheme of mould industry

Mold industry characteristics and management problems

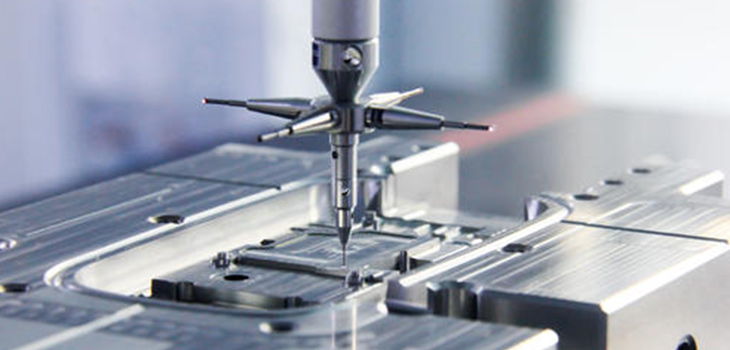

This is an era of knowledge management and professional management. With the increasing demands of customers for quality, delivery time, cost and service, does your enterprise need to solve the following problems to obtain better competitive advantage and profitability than its peers? The mold is a typical one-piece production, designed according to the order, discrete manufacturing. The design and manufacture of die are parallel, which is a process of design and manufacture. After receiving the order, the design department needs to design according to the user's product requirements. Except for standard parts, most non-standard parts need to be processed uniquely. Although the mold is the same, but the process plan and shape are different, so the process maintenance is difficult. The design change, rework and repair, adjustment and trial assembly in the production process make it difficult to grasp the punctuality and balance of the production plan. Each set of mould is a unique product of the enterprise, which makes the design and manufacture more complicated and the cost difficult to control.

- How to organize the production of dozens or even hundreds of molds at the same time?

- How to arrange the processing of parts with tens of thousands of ordinal numbers?

- How to quickly establish the part processing technology and estimate the standard working hours?

- How to realize the automation of design and processing?

- How to make quick and accurate mold quotation?

- How to master and control the production progress of mould in real time?

- How to arrange single operation and multi operation outsourcing of parts?

- How to make full use of the existing production resources and evaluate the production capacity?

- How to control the processing quality? Prevent unqualified parts from flowing to the next process?

- How to calculate the new mould cost and repair mould cost accurately and quickly?

ERP system solution of mould industry

Fangdee molderp mold management software is an enterprise level management software developed for the characteristics of mold, tooling and non-standard industries. From mold quotation, design, planning, procurement, machining, clamping, mold test, acceptance to receiving, returning, maintenance, maintenance and scrapping, the whole process management system is extended to the application of hardware, plastic, machinery and other industries to help customers realize the integrated management of enterprises. The system takes PDM design as the source, PS project as the main line, APS scheduling as the guidance, MES application as the basis, and financial management as the center, so as to ensure the quality of mold opening, reduce the cost of mold opening, shorten the business objectives of mold opening cycle, and realize the systematic management of mold enterprises.

- Provide a set of tools for mold project management to help mold engineers and management personnel follow up the mold production progress. The progress and delay are clear at a glance.

- Integrated with CAD and other design software, BOM is automatically generated by drawing.

- Standardize the design process, understand the design progress in real time, and automatically notify relevant personnel to handle design changes and exceptions, so as to minimize the loss of design changes.

- Cost analysis and quick and accurate quotation for samples or drawings provided by customers.

- Make the processing route and help the technicians estimate the planned working hours.

- Highly intelligent automatic production scheduling function, tens of seconds to complete tens of thousands of processes of automatic production scheduling.

- Fully consider the internal production capacity of the enterprise, and reasonably control overtime and outsourcing processing plan.

- The workshop personnel scan the bar code label and report to work without obstacles.

- Networking with CNC machine tools to realize intelligent and automatic production.

- Early warning of the service life of the mold, standardized test, repair, warehousing, maintenance and other processes.

粤公网安备 44190002004391号

粤公网安备 44190002004391号