Fangtian industrial cloud app: lightweight intelligent device cloud platform

Product characteristics

Small application and big benefitBased on SaaS application, import into cloud platform

No need to invest heavily in IT infrastructure, log in to Fang Tianyun directly

Standardized package plan, enjoy on demand in 1-3 days

Key applications

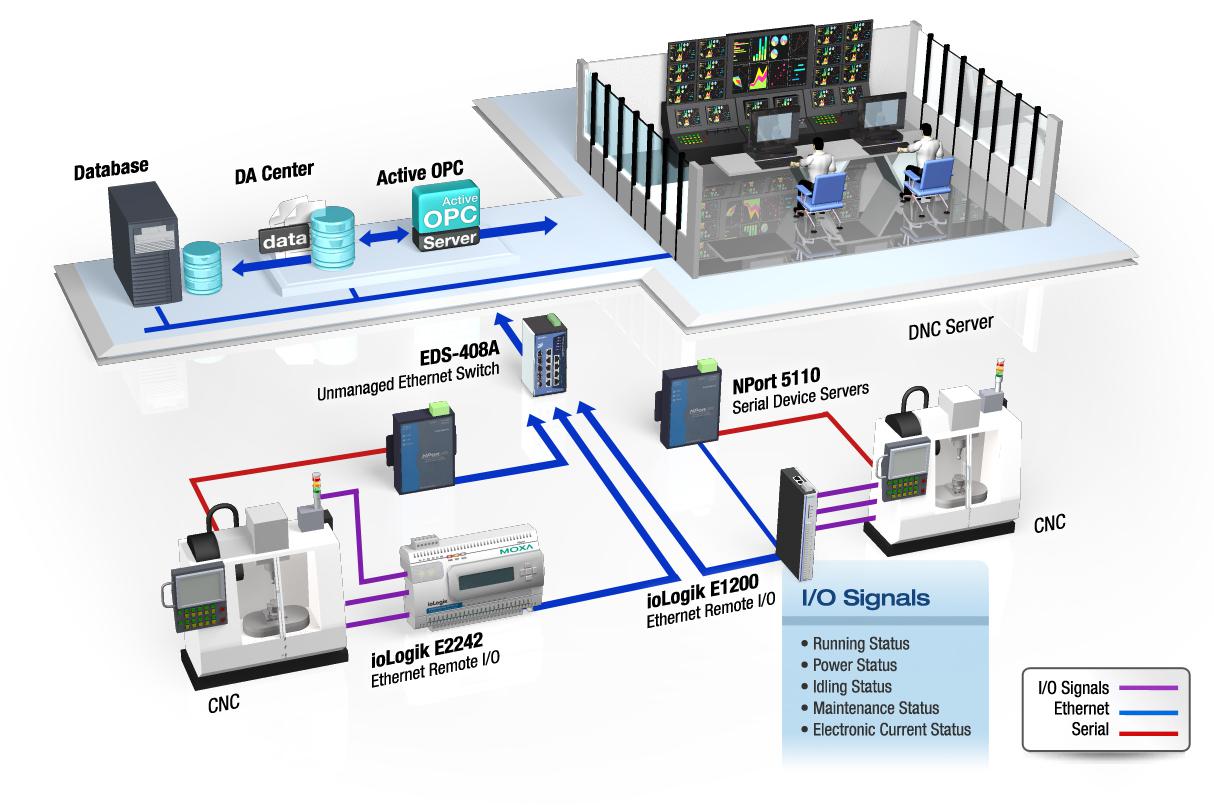

Smart factory first step to digitalize equipment networking

Difficulties: The real-time status of the entire machine is not easy to grasp, and the movement rate (including load) cannot be accurately controlled.

Countermeasures: equipment status monitoring, APP alarm notification, equipment harvest rate statistics, data visual output, and real-time display of workshop electronic signboards.

Achievements: The number of connected devices: 30, the equipment utilization rate increased by 23% (6 months), and the equipment failure waiting time was reduced by 45%.

粤公网安备 44190002004391号

粤公网安备 44190002004391号