Business excellence

20 years of technology precipitation and professional coaching team to help companies achieve business excellenceOverview of ERP solutions in the machinery industry

Mechanical industry characteristics and management difficulties

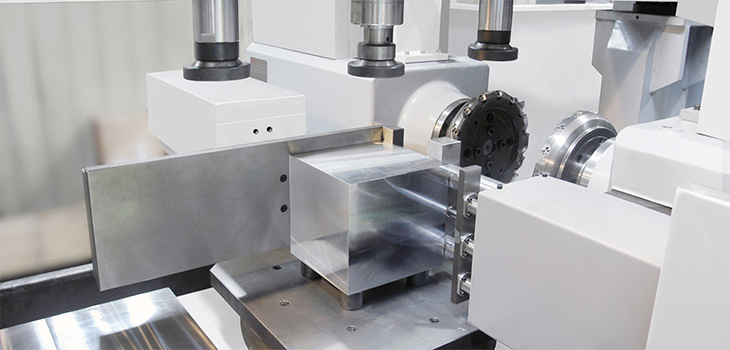

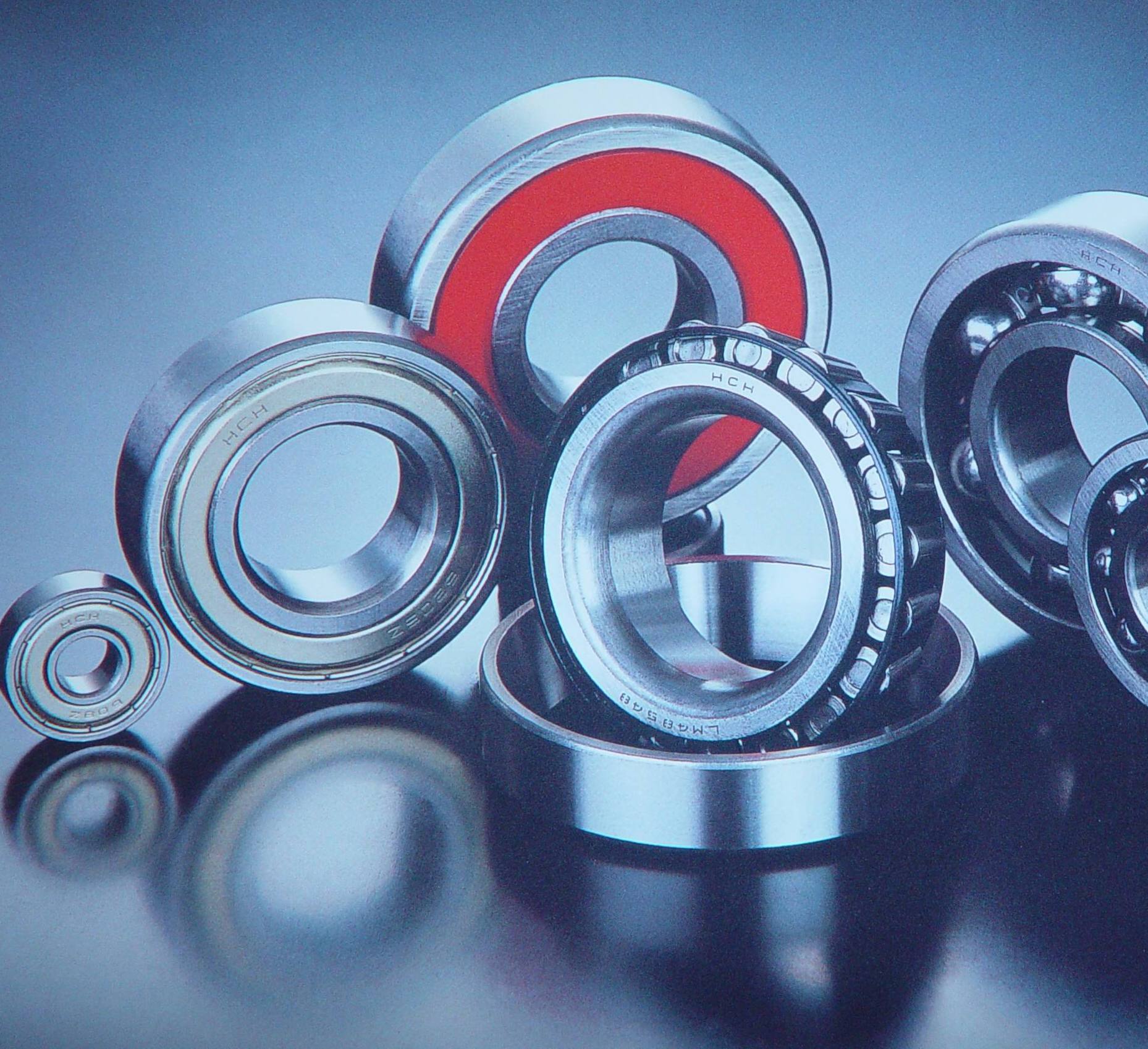

The main characteristics of production in the machinery manufacturing and assembly industry are discreteness, supplementary processes, and processing and assembly. The product structure (BOM) is complex and the engineering design tasks are onerous. The manufacturing process is complicated and the processing process is long. The production process requires a wide variety of machines and fixtures, long product life cycles, slow replacements, and difficult work in process management. The task of formulating production plans and production management is arduous, and self-made and outsourced processing often coexist. Due to the variety of products, parts and materials, and other uncertain factors affecting the production process, making production, outsourcing, and procurement plans difficult.

- Production by order is the main part, design by order, configuration by order, assembly by order and production by inventory are the secondary parts.

- The management of raw materials is simple, but there are many specifications of semi-finished products, in-process products and finished products, the coding is complex, the process is various, and the management is difficult.

- The general production process is that raw materials are cut or shaped into blanks, then processed by cutting (turning, milling, boring, grinding), semi-finished products are assembled, and finally assembled into finished products for shipment.

- The price of raw materials changes greatly, which makes the price management of purchase and sales complex.

- Production process often has outsourcing processing, such as electroplating, heat treatment and other processes.

- It is difficult to manage the leftover materials. There are many leftover materials in the production process (stamping and cutting). Some of them can be recycled.

- The processing route of product parts is long, and the work in process is difficult to manage.

- The manufacturing process is complex and the processing route is uncertain. There are many kinds of machines, equipments and jigs needed in the production process.

- The process is mainly based on equipment processing, and the capacity of the equipment determines the capacity of the production line.

- Serial number management is required to track product warranty period, maintenance records, etc.

ERP solution for machinery industry

The ERP system solution of Fangtian machinery industry, fully aiming at the industrial characteristics of complex process and in-process product management difficulties in machinery manufacturing and assembly industry, is a customized mechanical ERP management software, which effectively solves the management needs of customers in the industry, such as scattered information, difficult to control projects, numerous sales agencies, chaotic inventory and accounting, difficult to determine procurement plans, out of control production site, etc., and is widely used It is applied to all kinds of mechanical equipment enterprises, such as single design, single manufacturing, single assembly and mass customization. Realize the integrated management of mechanical processing enterprises from sales, procurement, production, quality inspection, after-sales, financial cost control, etc.

- Establish a multi-level product structure (BOM), expand the material, labor, cost, fast cost estimation and quotation according to the tree structure.

- Product structure and design change management, provide standard model quick configuration of non-standard model BOM to meet the requirements of different customers.

- According to BOM, enterprise inventory, order estimation, and the previous raw material purchase cycle and quantity, make a reasonable purchase plan.

- According to the BOM automatic production plan, all processes and operation processes are linked. All processes are reported by scanning codes, avoiding repeated entry and simplifying statistical work.

- Real time monitoring and tracking of WIP, the system can find out which production line and progress of WIP in real time, estimate the completion time of WIP, and guarantee the delivery time.

- The system supports the production mode of combining self-made and outsourcing processing. Product parts or special processes such as electroplating and painting will be commissioned to be processed by cooperative manufacturers.

- Exchange of multiple units of measurement for inventory, and effectively manage the dead materials and leftover materials.

- Batch number and serial number management are used to track the production batch, material batch, warranty period and maintenance records of products.

- According to the pre-set inspection items and standards, the whole process quality traceability of incoming inspection, process inspection, warehousing inspection, delivery inspection, etc.

- Powerful cost control and analysis function, cost calculation of materials, labor, manufacturing cost, outsourcing and other products.

粤公网安备 44190002004391号

粤公网安备 44190002004391号