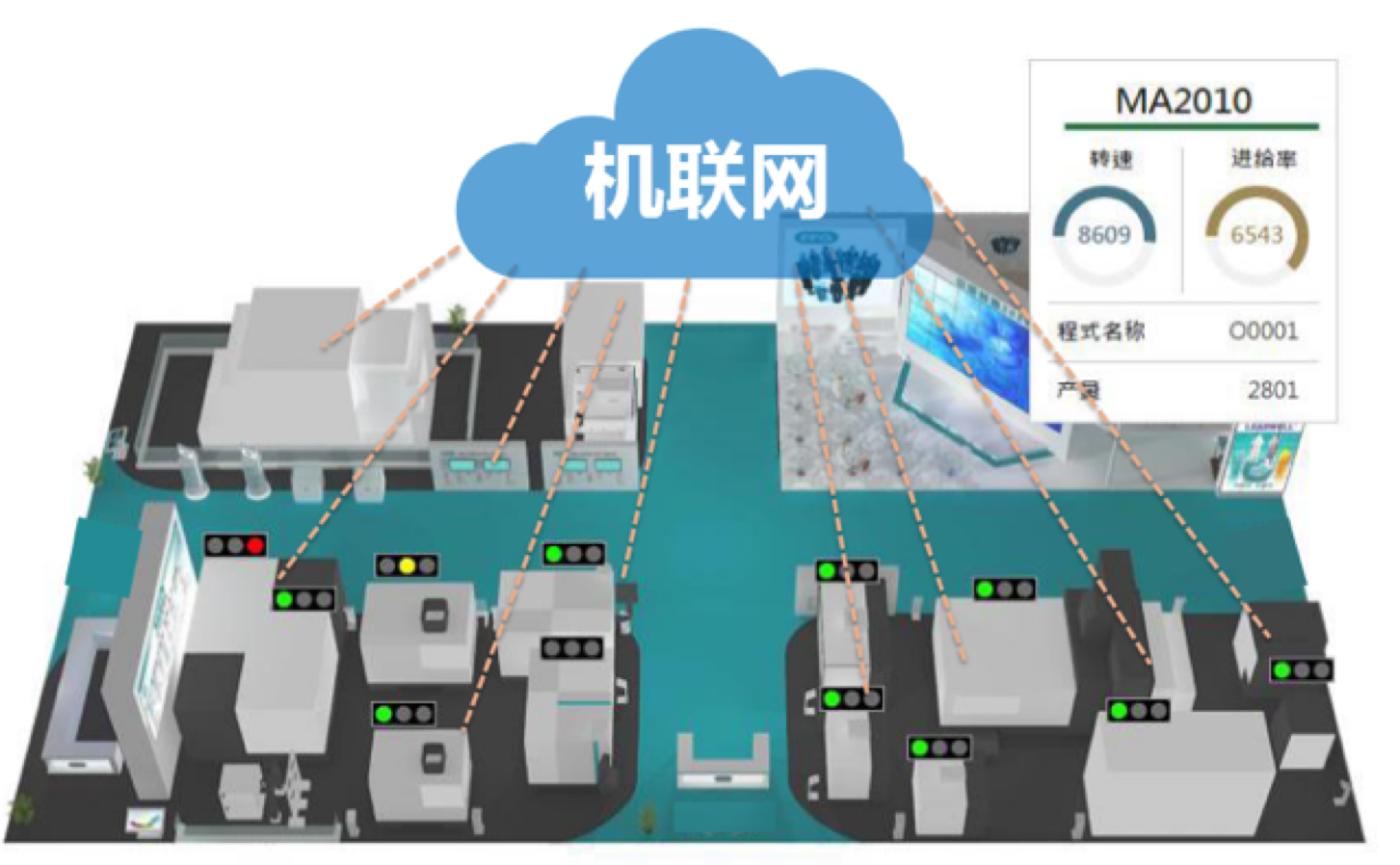

Fangdee MDC Machine Tool Networked Monitoring and Data Acquisition System

The Fangdee MDC system is an important part of the Fangdee software family. It is based on the networking of computers and realizes the interconnection and information exchange between systems and machines. Provide enterprise intelligent manufacturing solutions for smart factories, smart equipment and automation transformation enterprises. To achieve enterprises from product development and design, production process control, MES workshop execution, supply chain management, financial analysis, cost accounting and other overall system solutions.

Fangdee MDC system realizes the networking of machine tools in the whole factory through wired / wireless mode. It uses a cloud server to unified network management to help enterprises solve the problem of communication and management of processing programs, including transmission communication of NC programs and standardized management of NC programs. Realize the real-time analysis of collected data and automatic report to the workshop.

product features

Cloud networking monitoring of MDC CNC machine tools and OEE production rate statistics workshop board

Real-time device monitoring

Monitor equipment status and operating parameter information in real time.

Data acquisition and analysis

Provide management analysis reports such as equipment performance rate OEE and employee performance.

Automatic reporting of machine tools

Collect machine tool processing data to realize automatic reporting.

Key applications

Without adding any hardware, you can collect almost all information of the machine directly through the network cable

Data acquisition and analysis

Real-time monitoring equipment

Analysis of operating parameters

Production yield analysis

Equipment efficiency analysis

Production schedule management

Cloud remote monitoring

Statistical Management Report

Data acquisition and analysis

Realize the data collection of CNC machine tool turn-on and turn-off time, program start and end time, spindle load, spindle speed, feed speed, feed override, current running program, current number of workpieces processed, fault code, and error content.

粤公网安备 44190002004391号

粤公网安备 44190002004391号