Full traceability

From the start of planned production, process design and collection of production data, the complete production cycle of the product can be traced, including detailed production process data, used material information, and product shipment information, to achieve the receipt of production plans to product delivery to customers. The whole process is traceable.

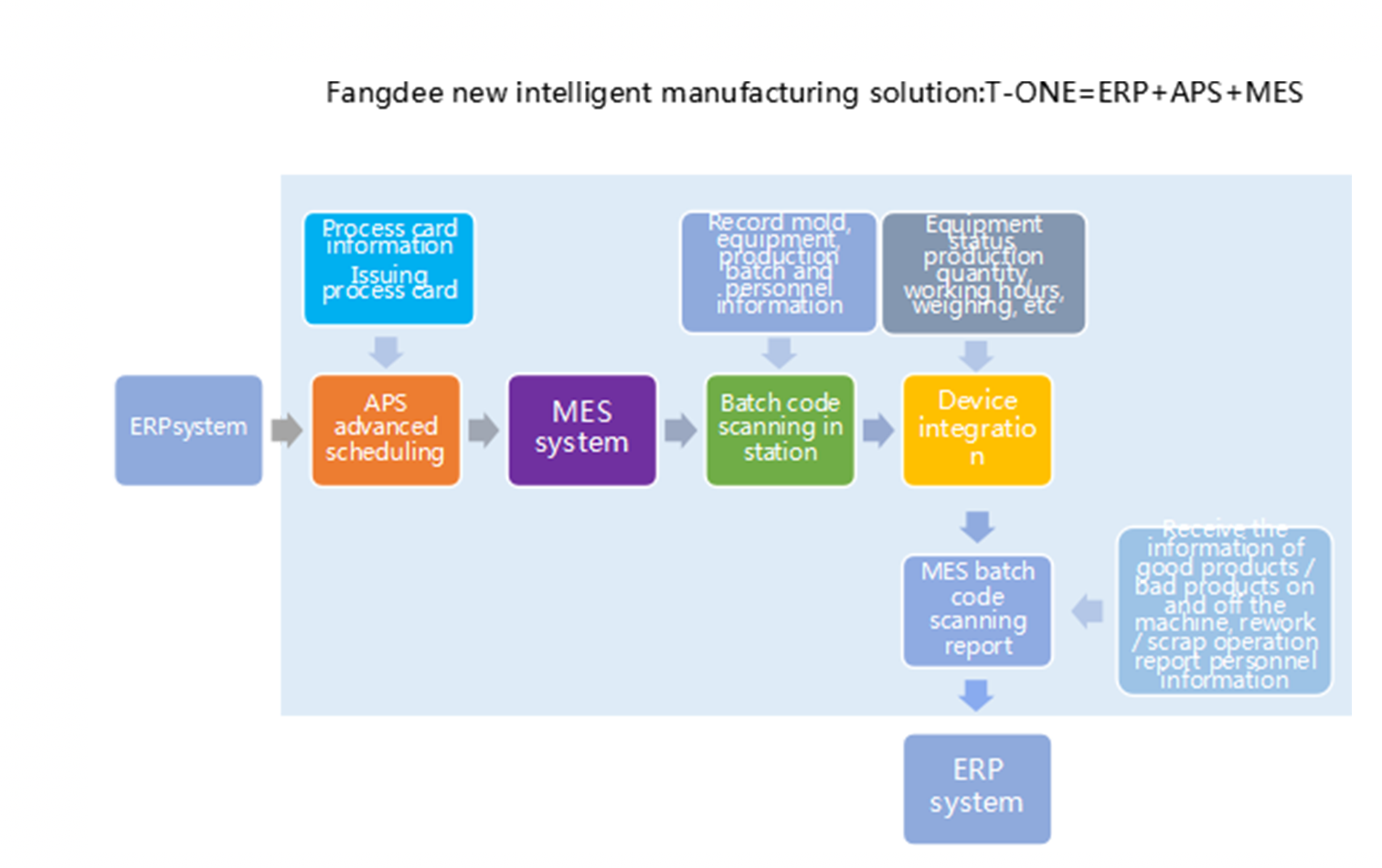

Plan production

Through scheduling visualization and analysis functions, resource-constrained scheduling is realized, which greatly reduces manual workload, frequent changes and unexpected situations, reduces manual method errors, achieves balanced production and improves production efficiency, shortens delivery time, and improves Capacity, reducing order overdue rates.

Process control

Machine networking, barcodes, mobile devices, electronic signage, ERP, to create the entire operation of the intelligent factory from procurement, picking, production, storage to delivery and after-sales. Standardization of material labels and transparency of in-plant logistics. The entire APP is presented in real time and recorded accurately.

Quality improvement

Through process error prevention, it is ensured that the product flows according to the pre-designed course, which reduces the behaviors such as skipping stations, missing stations, and missing tests, and ensures the integrity of the product production process. Verify the integrity of the operation steps of each process to prevent operators from missing operations during operation. Record and control quality checkpoints (QCs) to improve quality.

Machine tool networking

Through the device networking, you can view the running status, tools, alarm conditions, etc. of the device. It is based on the numerical control system, and realizes the integrated connection of CNC machine tools and MES through computer Ethernet communication technology, realizes equipment networking and performance control ability (OEE), and realizes manufacturing visualization, unmannedness and intelligence.

Visual management

Real-time grasp of the production data of each production line allows the team members to obtain the progress of the current production task at any time. Real-time notification of abnormal conditions on the site through electronic kanban, Mail, mobile phone APP and other methods, so that managers can understand the actual status of the production line in time and can respond quickly.

粤公网安备 44190002004391号

粤公网安备 44190002004391号