Business excellence

20 years of technology precipitation and professional coaching team to help companies achieve business excellenceERP scheme of precision parts processing industry

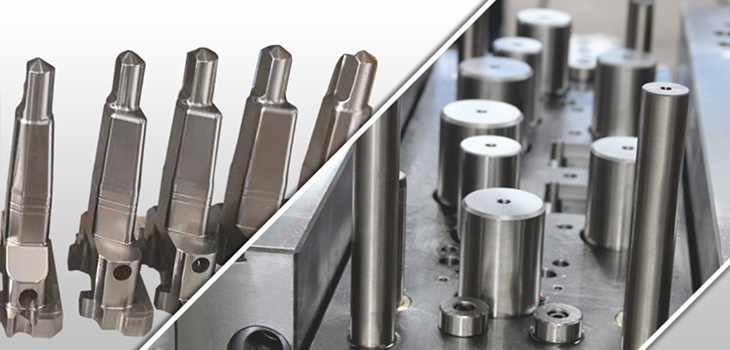

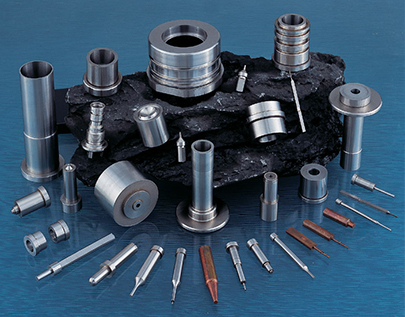

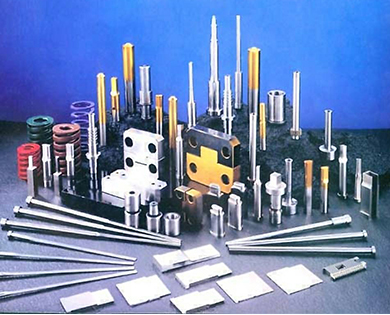

Characteristics and management problems of precision parts processing industry

The field management of parts processing industry is very difficult. Raw materials, work in progress, semi-finished products, finished products and leftover materials are all piled up on site, and the materials are not clearly marked, resulting in mixed use of materials, mixed assembly of products and confusion on site. The production mode adopts the combination of self-made and outsourcing processing, and the general electroplating, painting and other special processes will be entrusted to external manufacturers for processing. The quality and productivity of products depend on the technical level of workers to a great extent. Centralized bulk material purchase not only causes great inventory pressure, but also financial pressure.

- How to define standard parts and non-standard parts? How to code non-standard parts automatically?

- How to generate BOM quickly for non-standard machining parts?

- How to establish part process card quickly and evaluate part process time reasonably?

- How to use the existing production resources and capacity reasonably, effectively and fully?

- How to master and control the production progress of parts in real time?

- How to arrange the sequence of thousands, tens of thousands of processing?

- How to evaluate the current surplus production capacity of an enterprise? How to deal with outsourcing?

- How to count the rate of machine operation? How to count personnel performance?

- How to control and evaluate the machining quality of parts and prevent unqualified parts from flowing to the next process?

- How to analyze the deficiencies in the quality inspection work and promote the continuous improvement and improvement of quality?

- How to accurately calculate the material cost, labor cost and manufacturing cost of each processing part?

ERP solution for precision parts processing industry

The ERP solution of Fangtian precision parts processing industry is to establish multi-level BOM, process flow, processing equipment, processing time and other process parameters for precision parts processing, non-standard parts processing, standard parts processing industry, multi variety and small batch production mode, as well as complex manufacturing process, various tooling and fixture, large change of processing route, and difficult quality management, so as to establish the optimal process parameters Planning and scheduling. Help the production management personnel to understand the on-site production progress in time, timely pick up materials for production, outward processing or transfer to the next section, improve the on-site production efficiency, ensure smooth production, reduce material accumulation, and play a key role in improving the on-site management level. To meet the needs of enterprises for quality management, reduce inventory and financial pressure. A complete set of industry solutions from sales, procurement, production, warehouse, finance, cost, human resources and other comprehensive applications has been formed.

- Cost analysis and quick and accurate quotation for drawings provided by customers.

- Make the processing route and help the technicians estimate the planned working hours.

- Standardize the design process, understand the design progress in real time, and automatically notify relevant personnel to handle design changes and exceptions, so as to minimize the loss of design changes.

- Highly intelligent automatic production scheduling function, tens of seconds to complete tens of thousands of processes of automatic production scheduling.

- Fully consider the internal production capacity of the enterprise, and reasonably control overtime and outsourcing processing plan.

- Establish the whole logistics management from purchase requisition, inquiry, purchase, temporary receipt, acceptance and material issuance.

- Inventory provides multi unit bookkeeping of quantity / quantity, and can reflect the actual inventory at any time.

- Workshop personnel scan barcode and QR code labels, and report to work without obstacles.

- Automatically calculate production cost and loss, actual cost, and compare with estimated cost, analyze profit situation.

- Networking with CNC machine tools to realize intelligent and automatic production.

粤公网安备 44190002004391号

粤公网安备 44190002004391号