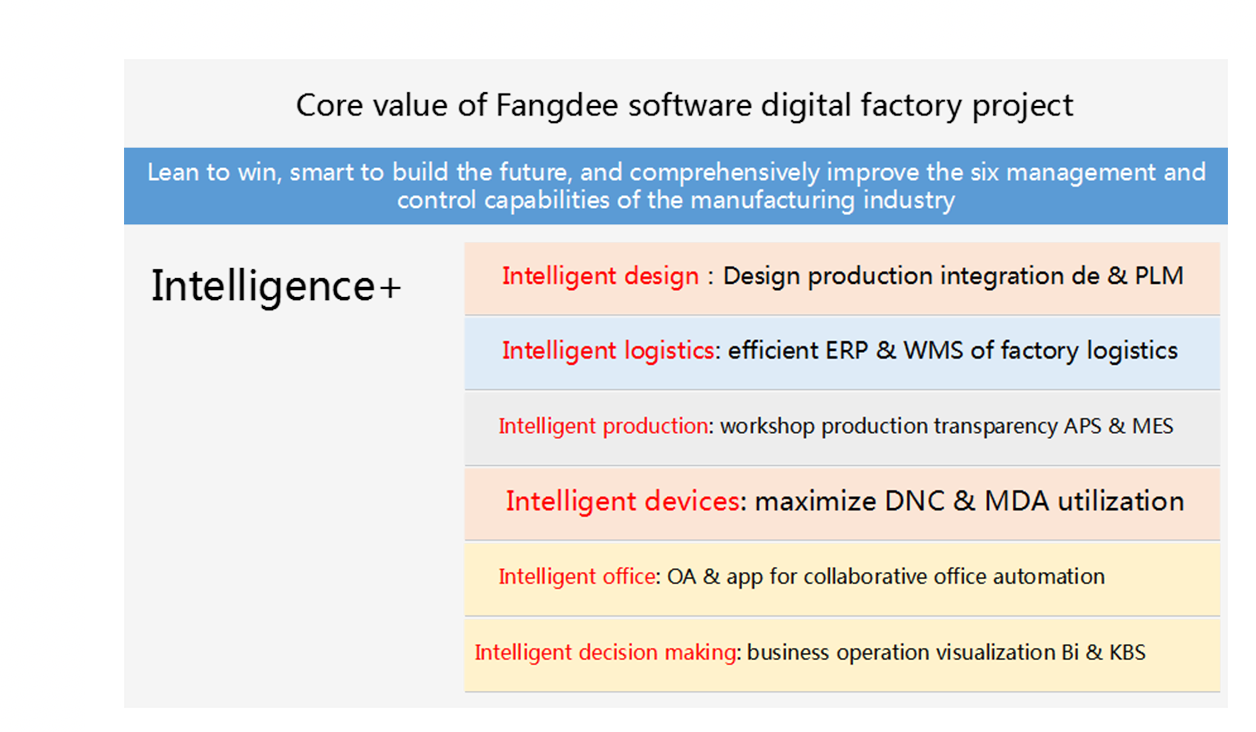

Design and production integration

Efficient factory logistics

Transparent workshop production

Maximize equipment utilization

Collaborative office automation

Visualization of business operations

Intelligent design: design and production integration

Make a dark horse from the design source. Open up the island of research and development information, realize the integration of design and production, and help enterprises transform into innovative companies.

A. High-efficiency collaboration for new project development;

B. Realization of internal, external organization, data and process collaboration;

C, shorten product development cycles, improve product quality, and reduce enterprise costs.

Intelligent logistics: efficient factory logistics

Serial barcodes, mobile devices, electronic signage, and ERP are used to create a full-scale operation in the intelligent factory from procurement, picking, production, storage to delivery and after-sales.

A. The standardization of material labels and the transparency of in-plant logistics;

B. The real-time APP is displayed in real time and recorded accurately;

C, fast nuclear material, nuclear library, nuclear quantity, nuclear batch, the entire process Quality traceability;

D, print boxes and labels in storage, quickly check shipments, and connect with the customer's receiving system;

E, real-time abnormal control, drive JIT, eliminate waiting and waste.

Intelligent production: transparent production in the workshop

Improve production site efficiency, order delivery capacity, and inventory turnover levels, improve the company's response to supporting needs, reduce production volatility, avoid inventory backlogs, and reduce labor waste.

A. MES production guided by ERP work order plan;

B. Strong APS scheduling capacity;

C, workshop production process reporting to work;

D, transparent production schedule;

E, Lean Production

Smart devices: maximizing device utilization

It is based on the numerical control system and realizes the integrated connection between the numerical control machine tool and the upper-layer MES through the computer Ethernet communication technology. It is the basic platform for enterprises to realize digital lean production. Achieve visualization, unmanned and intelligent production.

A. Through equipment networking, you can view the equipment's operating status, tools, alarm conditions, etc .;

B. Equipment networking and performance control capabilities (OEE);

C. It is written into Fangtian B9 according to the program name and automatically generates a process job order to realize automatic reporting.

Smart Office: Collaborative Office Automation

A new way of working

A. Mobile office: collaborative office at any time and place via the Internet / APP;

B. portable secretary: support custom warning conditions and warning content, so that abnormal conditions can be hidden nowhere; : All daily office forms can be set to support setting workflow and review flow.

Intelligent decision making: visualization of business operations

Visible to intelligent factory management: visual management eliminates many useless instructions, orders, and inquiries, which enables the management system to operate efficiently, enterprise business data visualization, and intelligent decision-making process.

A. Visual presentation of business management data;

B. Kanban-driven production JIT;

C. Timely management and control of abnormalities;

D. Provide Kanban that users can set.

粤公网安备 44190002004391号

粤公网安备 44190002004391号