Business excellence

20 years of technology precipitation and professional coaching team to help companies achieve business excellenceOverview of ERP solutions in the hardware industry

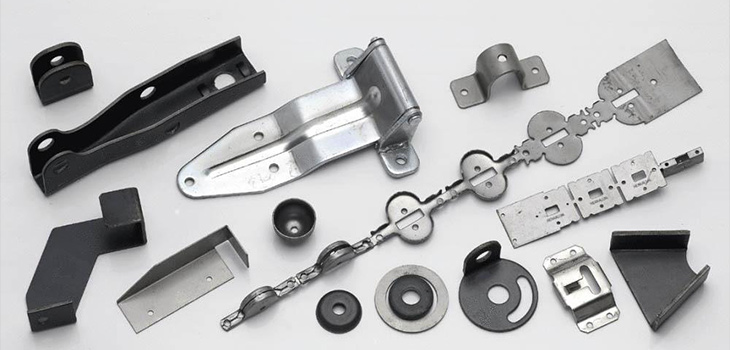

Characteristics and management problems of the hardware industry

On-site management in the hardware industry is difficult. Raw materials, work in progress, semi-finished products, finished products, and leftovers are all piled up on the site, and the materials are not clearly marked, which results in mixed materials, mixed products and on-site confusion. Product parts are made by combining self-made and outsourced processing. Generally, special processes such as electroplating and painting will be commissioned by external manufacturers. The quality and productivity of a product depend heavily on the skill level of the worker. Centralized bulk material purchases not only cause heavy inventory pressure, but also greater financial pressure.

- Iron plate / coil / iron tube (different materials). Mostly issued by the entire volume, online material management is important, material utilization and waste are more prominent.

- Inventory management requires quantity / weight dual unit accounting.

- There are many processing procedures, the process is complicated, and the work in process statistics is large.

- Some processes require outsourced surface treatment. Outbound inward and outward account management is more important.

- A work in progress account (input, output, non-performing, work in progress) and statistical reports for each workshop are required.

- A scheduling plan for each workshop is required.

- A statistical report of the capacity utilization rate and production efficiency of the machine is required.

- A piece-rate wage calculation is required, and the wage algorithm needs to consider stamper insurance requirements.

- Requires the estimated cost of the order and the estimated quotation function.

ERP solutions for the hardware industry

Fangdee Hardware Industry ERP solution is aimed at metal stamping, metal die-casting, screws, springs and other hardware products industries, multi-variety and small-batch production modes, complex manufacturing processes, numerous fixtures, large processing routes, and difficult quality management. Establish multi-level BOM, process parameters, processing equipment, processing time and other process parameters, and formulate the optimal schedule. Help the production management staff to timely understand the progress of the on-site production, timely pick up production, outsource processing or transfer to the next section, improve on-site production efficiency, ensure smooth production, reduce material accumulation, and play a key role in improving on-site management. Meet the needs of enterprises for quality management and reduce inventory and financial pressure. Formed a complete set of comprehensive industry solutions from sales, procurement, production, warehouse, finance, cost, human resources and other applications.

- For the whole volume picking and distribution, the whole volume is transferred to the online WIP warehouse first, and then the material in production is calculated according to the method of reverse calculation of consumption in the stock in order to make a cutting knot for a whole volume.

- Inventory provides multi unit bookkeeping of quantity / quantity, and can reflect the actual inventory at any time.

- Provide real-time status (WIP) of & ldquo; WIP & rdquo.

- Provide outward delivery in and out deposit account and statement with the third party manufacturer.

- Make statistics of the utilization rate of the whole roll of the production line to reduce waste.

- Automatically reflect production progress and order fulfillment.

- Automatically calculate production cost and loss.

- Automatic statistics of product qualification rate and equipment utilization rate.

- The merchandiser can click the order tracking button to complete the downstream purchase / production and outsourcing progress.

- Accurately generate estimated cost and actual cost of orders, and can be compared and analyzed.

- Calculate the piece work wage of each workshop automatically.

- Support bar code, networking with stamping machine, die-casting machine and other machines to realize paperless and automatic production.

粤公网安备 44190002004391号

粤公网安备 44190002004391号